FEA analysis / structural simulation

Our range of services

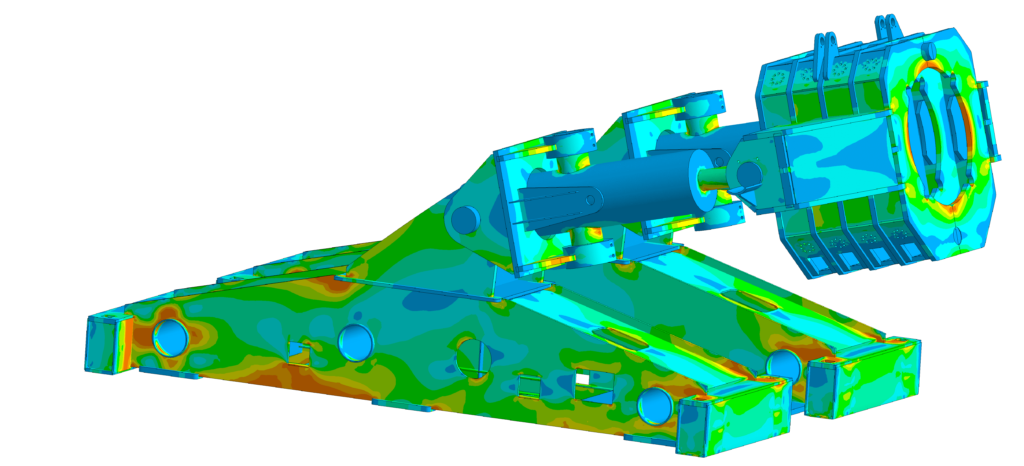

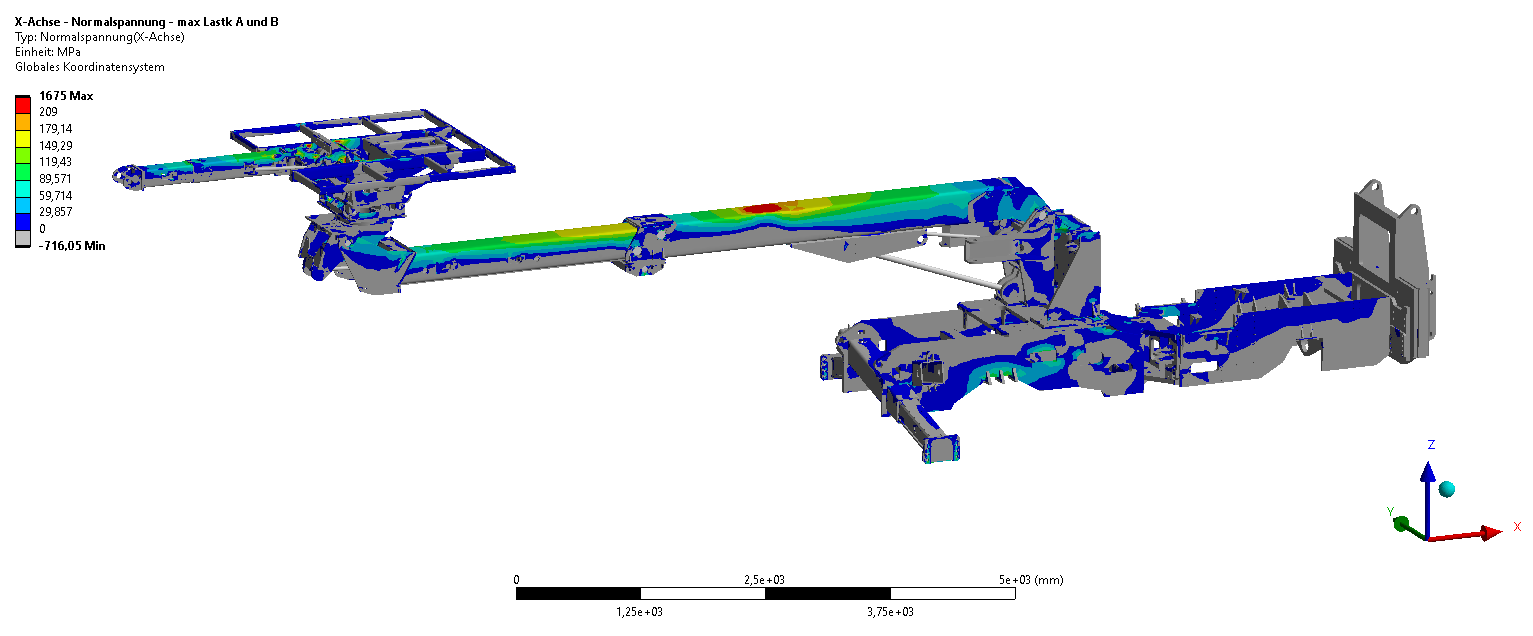

FEA analyses are a helpful tool for product development in order to visualize the behaviour of materials, components and assemblies under different conditions or loads. Errors in the construction or design can be detected at an early stage with the help of a structural simulation. This allows you to save valuable time and resources while maximizing your profits.

As a FEA service provider, we use FEA calculations to make physics visible and provide you with digital insights into your product development that would otherwise have remained physically hidden. This not only saves you time but also your valuable resources.

Other compelling reasons for using FEA calculations and simulations:

- You need a verifiable proof of strength as part of the documentation. Or support with the CE marking of your products on the basis of the Machinery Directive 2006/42/EC.

- You want calculations on virtual prototypes during development to ensure the functionality of your components or to control weight, quality and costs.

- You want to assess risks in advance using simulation in order to realize shorter development times and thus a faster market entry.

- You want to visualize the physics (deformations, stresses, currents, temperatures, type of failure) statically or in the time domain in order to better understand the behavior of your components.

- You want to test variants or carry out parameter studies, but real tests take too long or are too expensive. Or you need a comparison between real tests and the simulation. We can deliver both for you

- You want to find out as quickly as possible whether a component will hold or not – without time-consuming documentation or extensive calculations. Our engineering office for simulation and virtual product development makes it possible!

Advantages of FEA calculations

Analysis of product properties

By using Finite element analysis, product properties such as vibration behavior and load limits can be determined during the planning stage. This allows you to identify the optimization potential of your product at an early stage and gives you peace of mind.

Cost-efficient prototypes

Structural simulations can be used to carry out calculations on virtual prototypes during development. FEA Calculations are therefore more cost-efficient than conventional prototypes and allow you to simulate changes quickly.

Quickly ready for series production

With the use of structural simulations, tests can be reduced and series production can be achieved more quickly. With our support, you can identify unfavourable behaviour of your components at an early stage and make appropriate optimizations.

Reduction of the testing effort

Test phases can be significantly shortened as changes can be simulated and calculated quickly and cost-effectively. Trials can be reduced to a necessary minimum.

Our reference projects

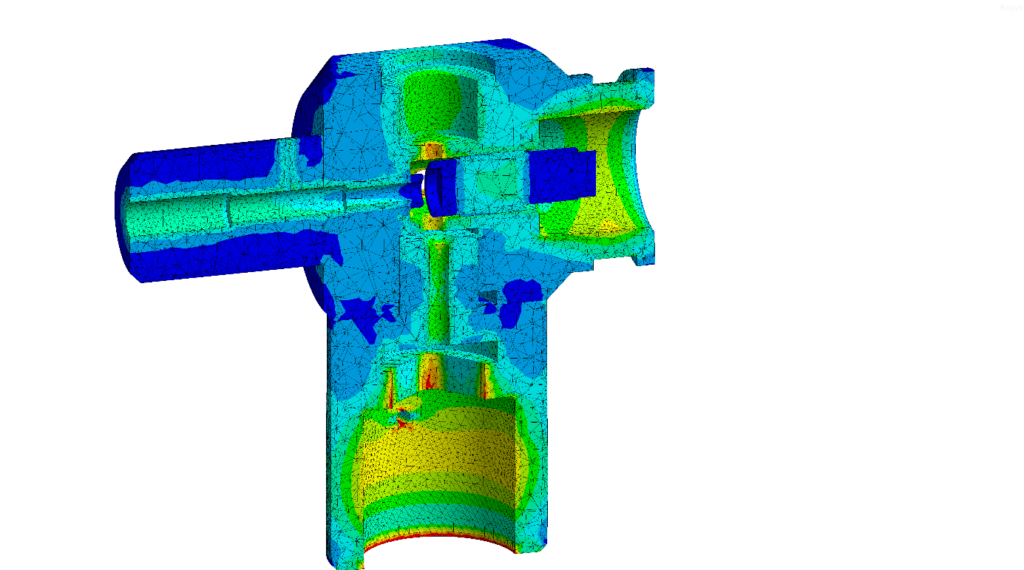

Static strength verification of the shut-off valve in accordance with DIN EN 13445-12 at room temperature under a test pressure of 570 bar and an operating pressure of 380 bar. The threads (brass screws / internal thread) have been analytically and conservatively verified with regard to their resistance to stripping in accordance with VDI 2230.

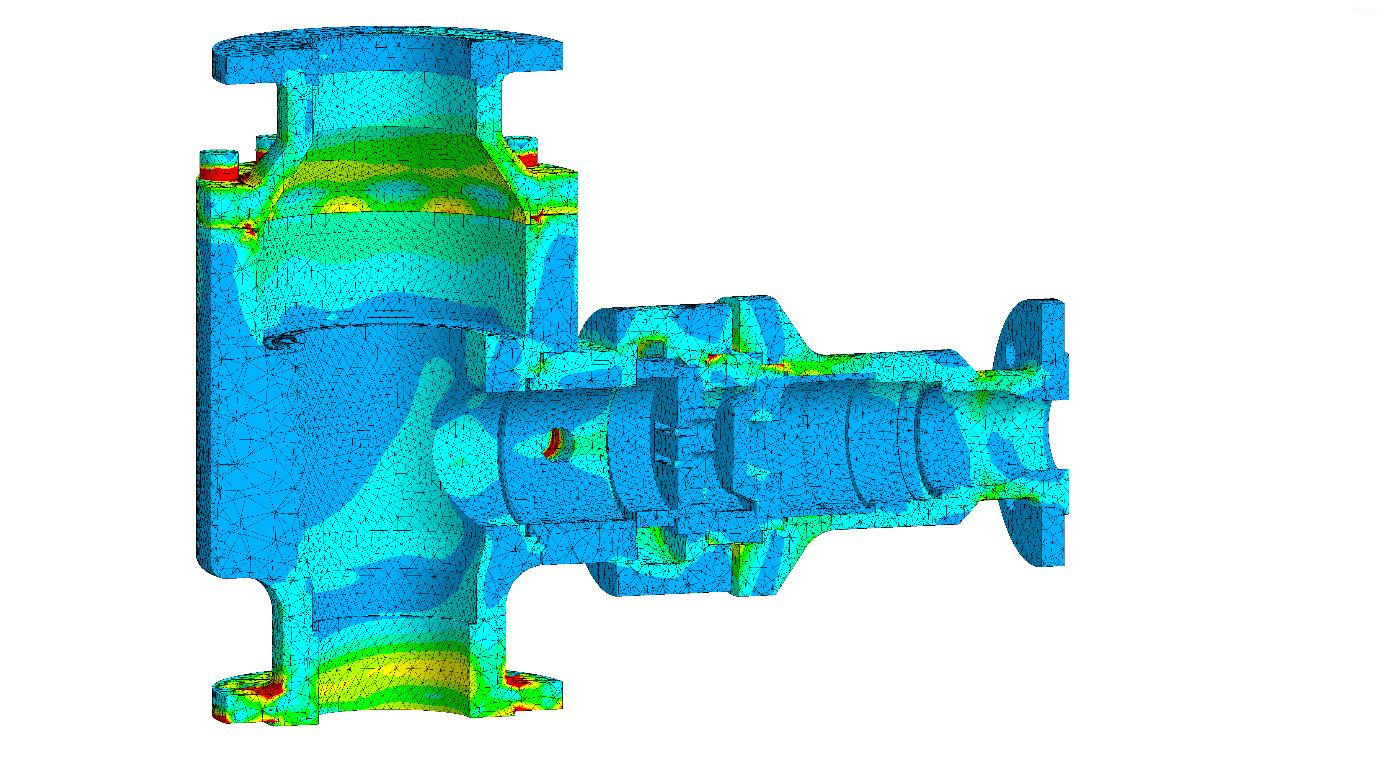

Proof of an automatic pump protection valve to ensure the minimum flow rate of a pump and to protect against overheating, cavitation and damage.

Strength, fatigue and stability testing of a lifting machine for setting heavy support arches using a combination of different standards with a very complex geometry. The lifting machine is equipped with articulated steering and all-wheel drive and has a load capacity of 2,000 kg with a maximum platform height of 9.8 m.

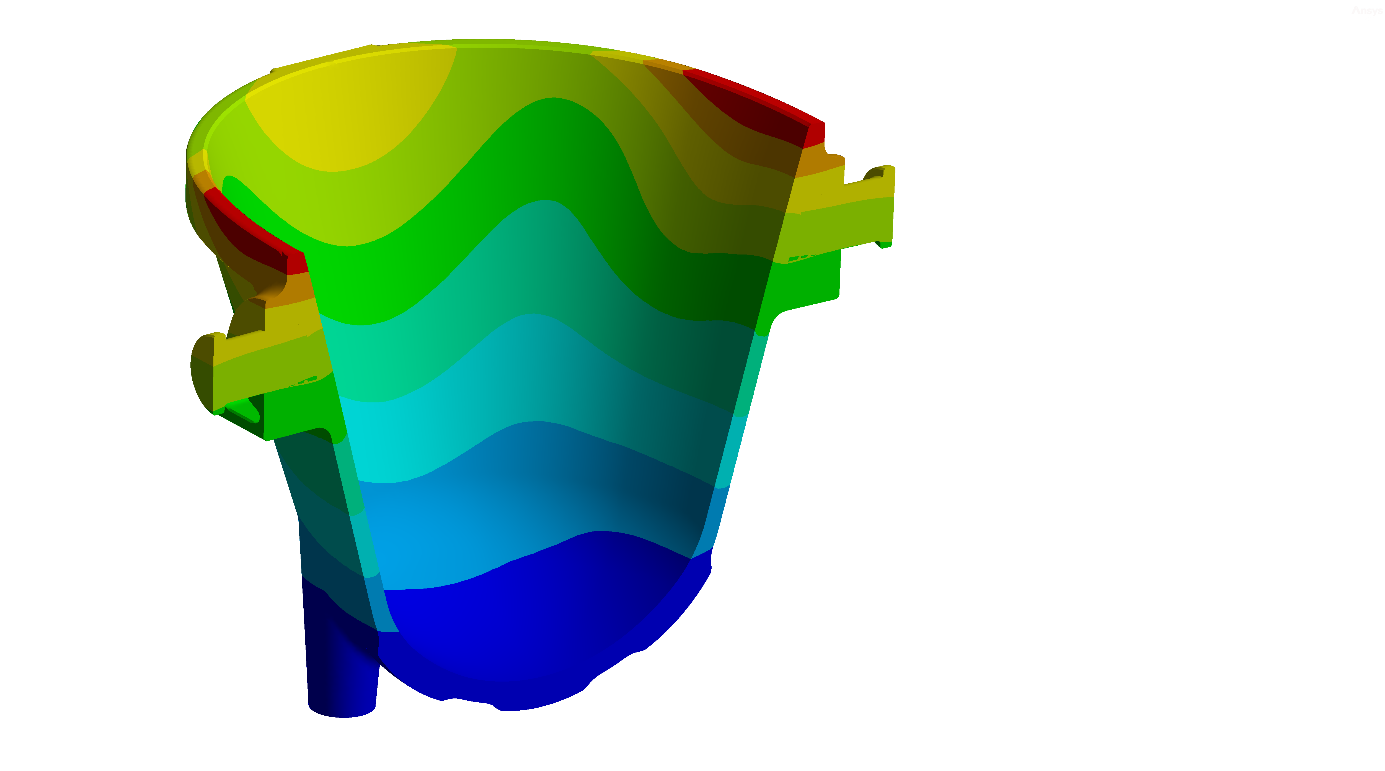

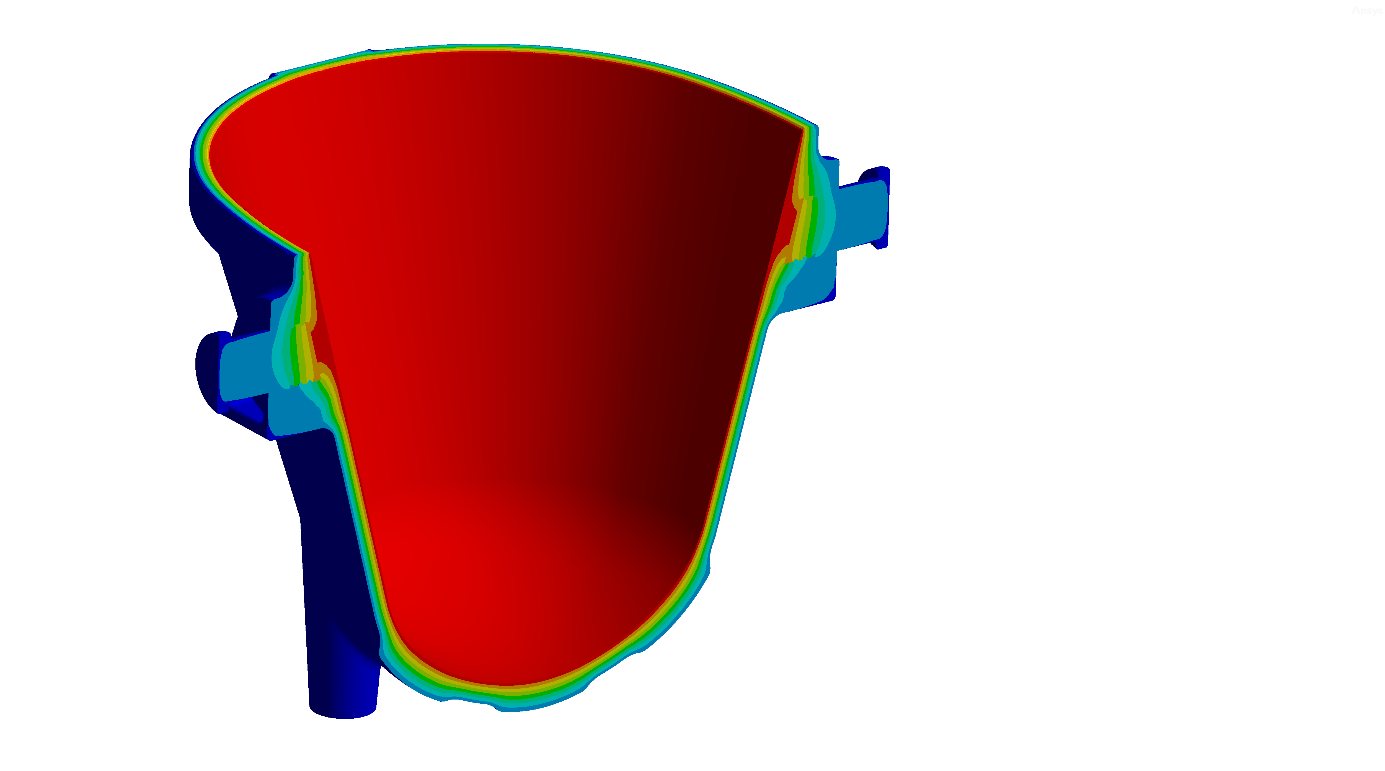

Static calculation of a slag bucket with a dead weight of 33 tons, a theoretically fillable volume of 16.5 m³ and a specific density of the slag of 3.6 t/m³.

Due to the high temperature of the slag (1,320°C) and the calculations of the bucket within a temperature range of 200 – 800°C, no common standard was applicable, so we developed a validation concept in combination with the FKM guideline and Eurocode 3.

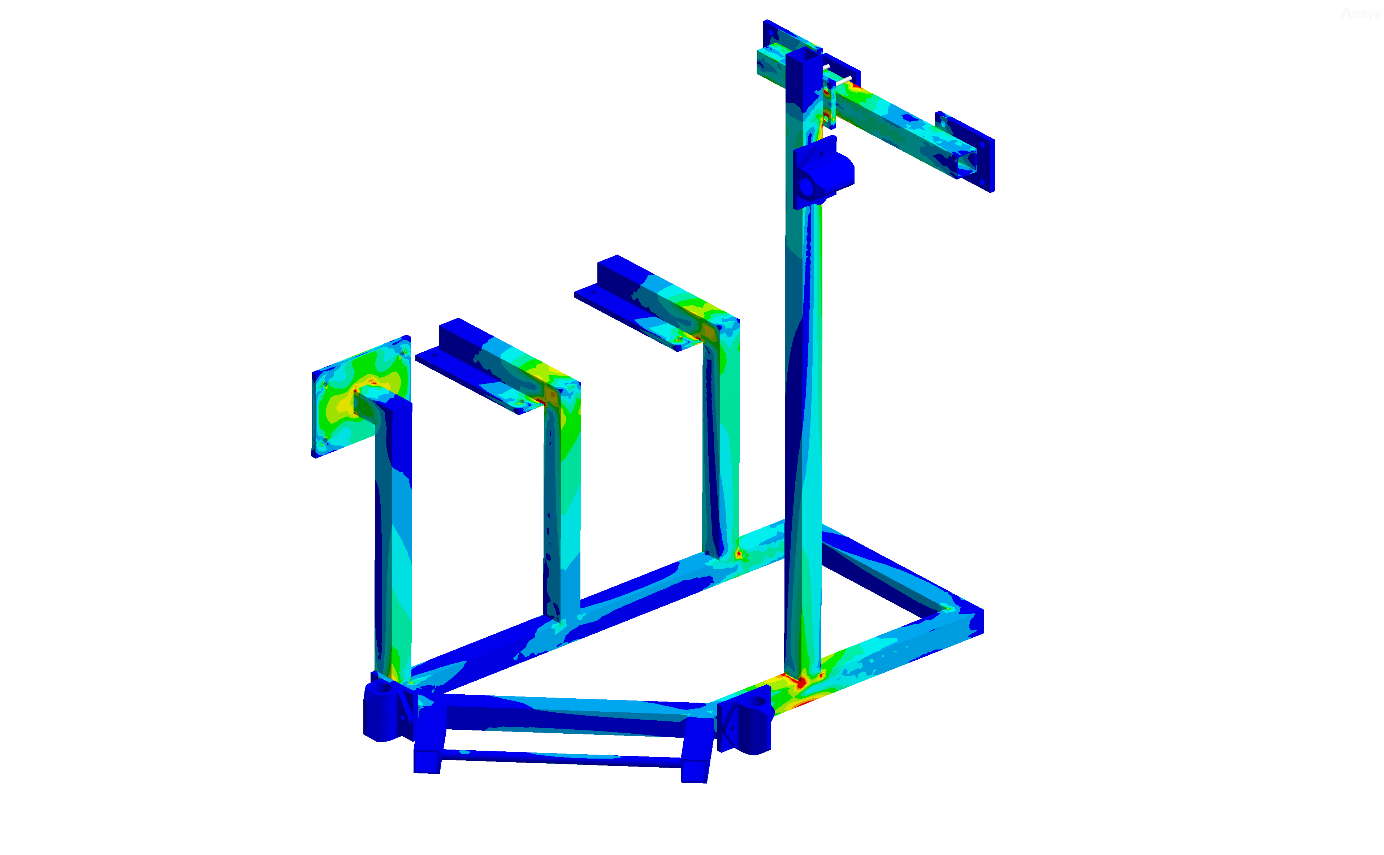

Structural analysis in accordance with Eurocode 3 of a small maintenance platform (75 kg dead weight), accessible by one person, including tools. The platform consists of a combination of structural steel, aluminum and clamp connections.

Your FEA service provider

As an experienced FEA calculation office, we offer you professional engineering services in the field of FEA calculations and simulations. Our team of motivated and competent engineers has decades of experience in the calculation and simulation of complex components. Our incentive is to offer our customers the best possible support in the development and optimization of their products.

Please contact us if we can support you.

We look forward to hearing from you.

KONSCHA Simulation GmbH

Our services

- FEA Calculation as a service

- Stability (denting and buckling)

- Screw calculation

- Pressure vessels (AD2000, EN13445, ASME Section 3+8)

- Strength verifications / stability verifications

- Analyze component behavior

- Fatigue strength (fatigue)

- Weld seam calculation

FAQ

For every analysis we carry out, you will receive a verifiable calculation report, the FE model with which the calculation was carried out and if desired, we will advise you and provide optimization suggestions.

The processing time depends, among other things, on the scope of the project, our order situation and our capacities. In most cases, we can process smaller projects promptly.

We require the following data to prepare a quotation:

- 3D cad geometry (step or iges format) or a technical drawing or sketch

- Information on the materials used

- Information on the loads acting on the structure such as forces, accelerations, pressures, temperatures

Make a non-binding inquiry and our experts will let you know what additional information we need.

Unfortunately, we cannot give a generalized cost for a structural simulation as it depends on various factors. To name just a few examples:

- Geometry: number and complexity of solids

- Material: linear or non-linear

- Connection of the bodies: screw connection, welded connection

- …

Please contact us and we will prepare an individual offer for you.

Do you still have questions about FEA calculations, analyses and simulations? Write to us with your request and we will get back to you as soon as possible

Do you need a verifiable proof of strength? You want to assess risks in advance using simulation in order to realize shorter development times and thus a faster market entry. We are your competent service provider for FEA calculations and structural simulations and deal with issues ranging from simple strength calculations to complex models of fracture mechanics.

KONSCHA Simulation GmbH

Lerchenstr. 28a

22767 Hamburg

Phone: +49 (0)40 / 2285 9289 – 2

E-mail: info@konscha-simulation.de