Fatigue strength verifications

- Your service provider for fatigue, endurance and fatigue strength verifications

- Identification of weak points and potential for improvement

- Targeted advice for your projects

- Individual and practical

Fatigue strength verifications - Stresses in detail

Fatigue of a material refers to failure due to repeated, cyclical loads. The allowable limit of these loads can be significantly lower than the static loads.

- Load spectrum recording: First, the load spectrum is determined, i.e. the type, frequency and intensity of the cyclical loads occurring during operation

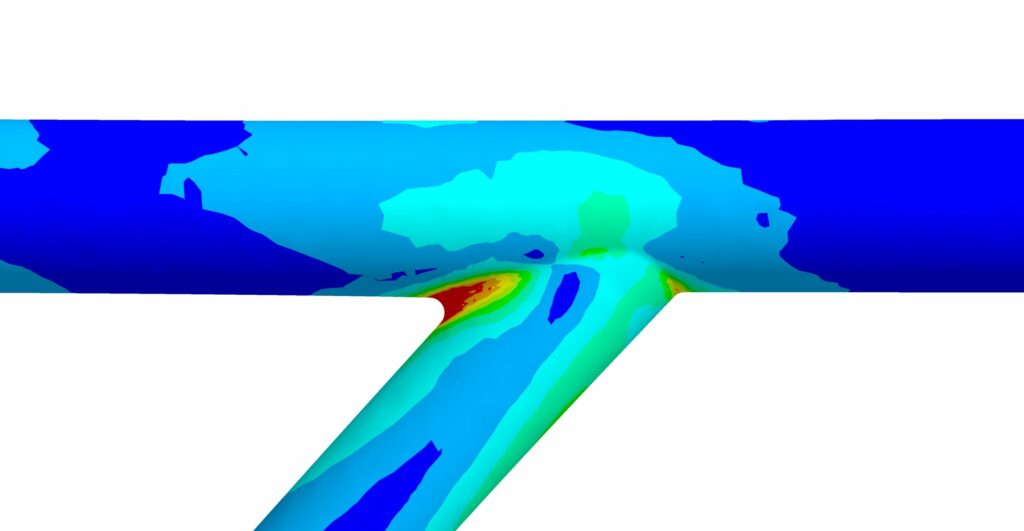

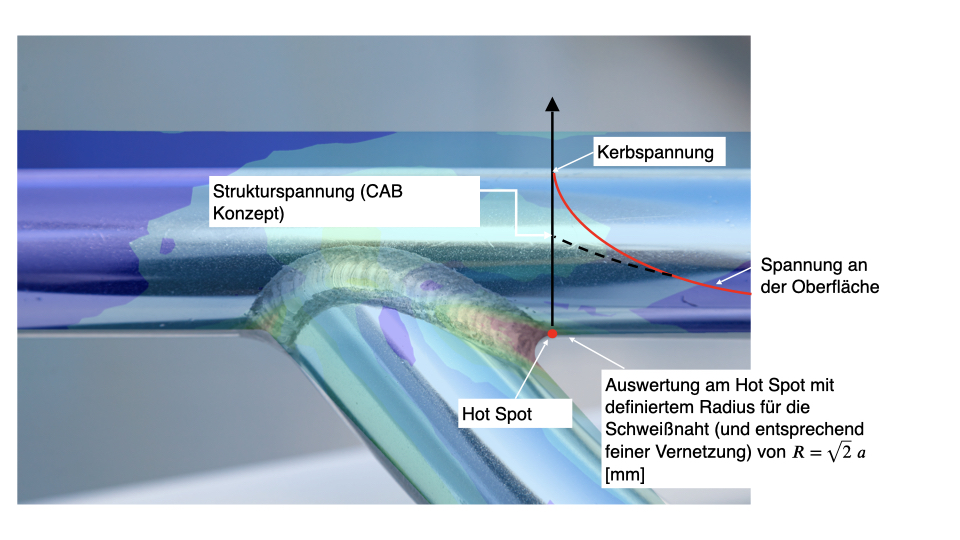

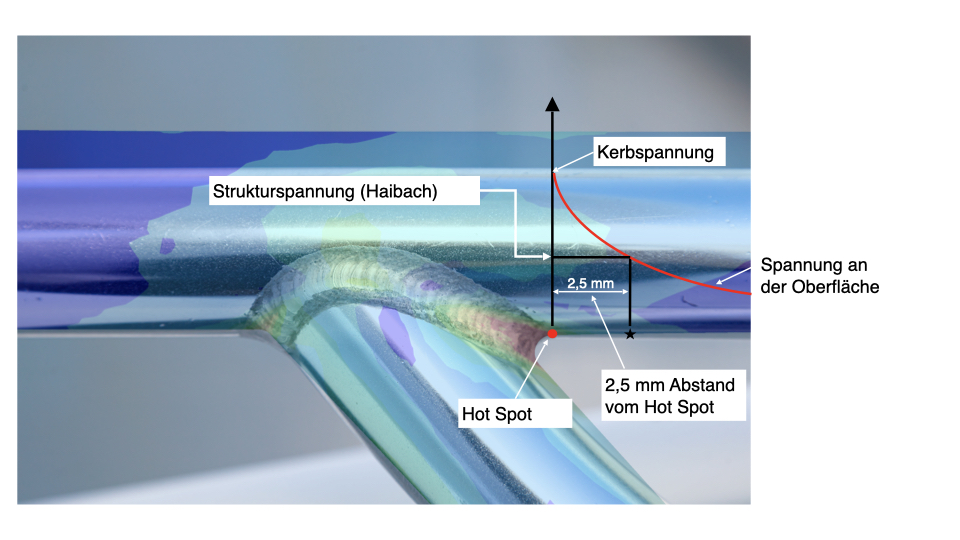

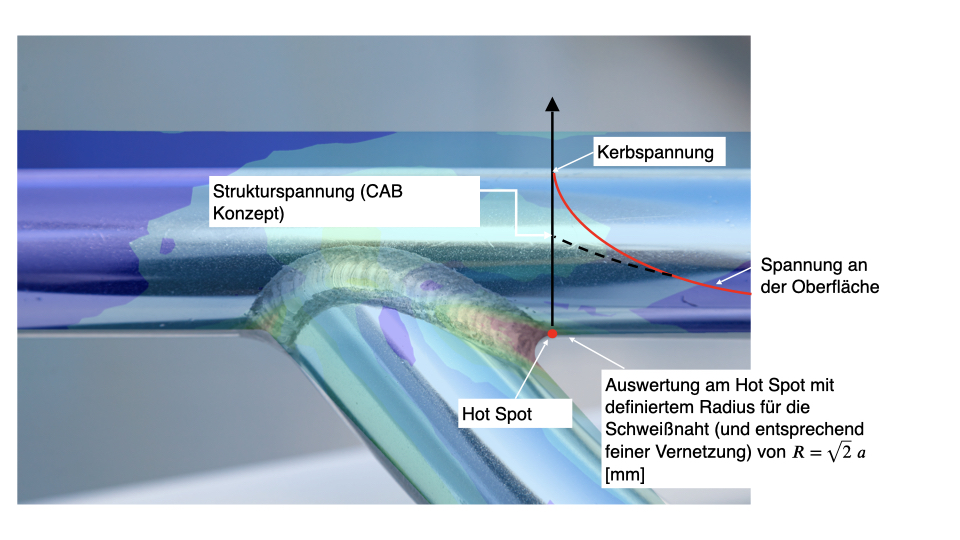

- Stress analysis: Finite element methods (FEA) or other analysis methods are used to identify the stress distributions and critical points in the component, e.g. at notches or weld seams.

- Material data determination: The material characteristics, such as the Wöhler curve, are usually taken from the standards or guidelines.

- Service life calculation: The service life of the component is calculated based on the stress analysis and the material data. The number of load cycles until failure is determined.

- Verification: The calculated service life of the component is compared with the requirements and validated by safety factors to ensure operational safety.

If damage has already occurred, such as the appearance of cracks, we can help to analyze the causes and develop measures to prevent consequential damage. We can also calculate how long a component can still be operated safely before it needs to be replaced.

Example of fatigue strength

Our services

Verification of fatigue, fatigue strength and operational stability in various industries

- Waste and recycling technology systems

- Refrigeration and heat pump technology, air conditioning and ventilation technology and drying technology

- Pumps, valves and fittings

- Printing and paper technology

- Machines for processing wood

- Machines for the production of plastic or rubber

- Food processing machines and packaging machines

- Machines and systems for the manufacture of pharmaceutical and cosmetic products

- Machine tools

- Drive and conveyor technology

- Energy plant construction (hydropower and wind turbines)

- Process engineering machinery and equipment

Determination of the physical behavior

- Use of the latest software tools

- Verifiable proof of strength in accordance with current standards and guidelines

- Detailed reports and documentation for submission to authorities and clients

Identification of weak points and potential for improvement

- Optimization of constructions

- Development of optimized solutions to increase strength and stability

- Support with material selection and design

Evaluation aid following the detection of cracks

- Crack propagation calculations can estimate the service life of a component until the crack becomes unstable and thus enable the production of spare parts, for example

Engineering office for fatigue strength analysis

KONSCHA SIMULATION GmbH offers you comprehensive support for fatigue strength verifications / fatigue strength verifications. With decades of experience in the calculation and simulation of complex components, our experienced engineers are at your side. We strive to support your product development and optimization in an efficient and targeted manner.

Feel free to contact us – we look forward to your inquiry and to providing you with competent support.

KONSCHA Simulation GmbH

Standards and directives - Fatigue strength

All strength verifications, including consideration of fatigue strength, are carried out in accordance with the applicable standards and guidelines.

- FKM Guideline (Calculated strength verification of machine components)

- Eurocode 3 - DIN EN 1993 (Design and construction of steel structures)

- EN 13445 (pressure vessels)

- AD 2000 (pressure vessel)

- VDI 2230 (bolted connections)

- and other relevant regulations

Advantages of the strength analysis of components

Prevention of component failure

A fatigue strength verification can be used to ensure that the component can withstand the loads acting on it. This protects people and property.

Dimensioning of components

Optimization of constructions

The results can be used to optimize the design. This reduces costs and can improve the availability of semi-finished products.

Do you need proof of fatigue strength? Just write to us - we will get back to you as soon as possible!

As your experienced engineering office, we offer comprehensive solutions for static strength verifications and are at your side for all questions relating to fatigue strength, fatigue strength, fatigue strength and operational strength.

KONSCHA Simulation GmbH

Lerchenstr. 28a

22767 Hamburg

Phone: +49 (0)40 / 2285 9289 – 2

E-mail: info@konscha-simulation.de