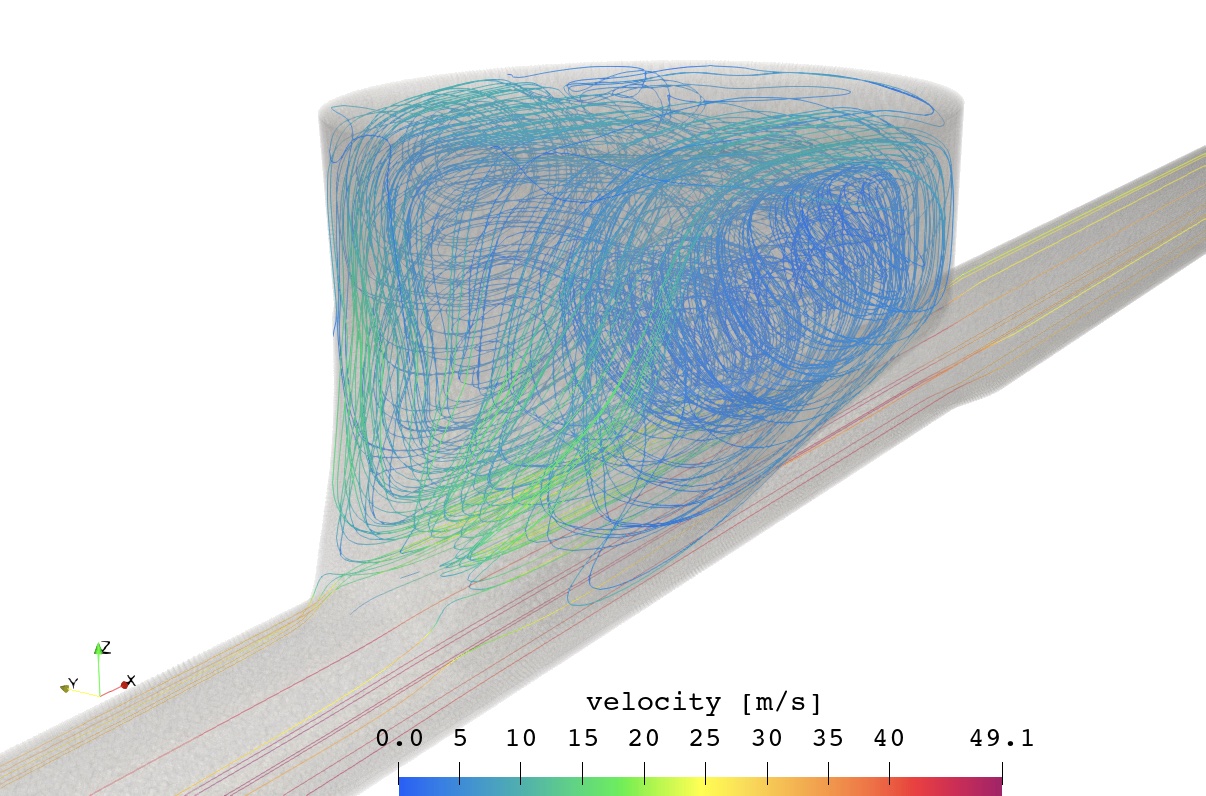

CFD calculation / flow simulation

Our services as a CFD service provider

CFD (computational fluid dynamics or numerical flow simulation) is used in practical applications to calculate temperature, velocity and pressure distribution. This is generally much cheaper and quicker to implement than corresponding tests, e.g. in wind tunnels.

Typical industries, topics and tasks in which calculation and simulation has established itself as a tool are listed below. If you cannot find your topic here, please contact us!

- Flow around systems and vehicles

- Whether car, ship or airplane – the lower the flow resistance, the lower the required drive power. Therefore, the optimization of the external geometry is a typical task for CFD simulation

- Flow-optimized bodies are subject to less mechanical stress

- Calculation of vibrations due to detachment effects in order to exclude these effects from the outset.

- Determination of Transient or steady state loads as input variables for subsequent strength calculations

- Flow in components / mixing processes

- Calculation of efficiency and pressure losses in pumps, valves, heat exchangers, fittings, pipelines, etc.

- Calculation of cavitation, e.g. on impellers or propeller blades. This serves to optimize speed profiles, which prevents damage

- Calculation of mixing processes, e.g. in agitators or exhaust gas systems

- Optimization of the geometry, e.g. of filling systems, to create the same flow conditions

- Filling processes from the pressure vessel sector

- Heating and cooling processes / temperature distribution

- Calculation of heat distribution in industrial plants

- Design of heat exchangers or chillers

- Cooling of power electronics, heat development in batteries, etc.

Advantages of CFD calculation

Analysis of product properties

With the help of numerical CFD calculations , product properties such as air flow, flow and temperature distribution in components can be determined during the planning stage. This allows you to identify the optimization potential of your product at an early stage and gives you peace of mind.

Cost-efficient prototypes

Flow simulations can be used to carry out calculations on virtual prototypes during development. CFD calculations are therefore more cost-efficient than conventional prototypes and allow changes to be simulated quickly.

Quickly ready for series production

With the use of flow simulations and temperature calculations , tests can be reduced and series maturity can be achieved more quickly. With our support, you can identify faulty parts of your product at an early stage and make appropriate optimizations.

Reduction of the testing effort

Test phases can be significantly shortened as changes can be simulated and calculated quickly and cost-effectively. Trials can be reduced to a necessary minimum.

Our reference projects

Determination of velocity and pressure distributions within the feed shoe for mineral processing and bulk solids plants

Engineering office for CFD calculations & simulations

We, KONSCHA SIMULATION GmbH, are your reliable CFD service provider for professional flow simulations and CFD calculations. Our highly qualified team of engineers has decades of expertise in the simulation and analysis of complex components. As a leading CFD provider, our focus is on providing you with the best possible support in the development and optimization of your products with precise and effective solutions.

Feel free to contact us if you are looking for an experienced CFD service provider.

We look forward to hearing from you.

KONSCHA Simulation GmbH

CFD provider

Our services

- CFD calculations as a service

- Flow around systems

- Mixing processes

- Analysis of the temperature distribution

- Cooling of power electronics

- Analysis of the flow in components

- Heating and cooling processes

- Calculation of heat distributions

FAQ

For every analysis we carry out, you receive a verifiable calculation report, the models with which the with which the calculation was carried out and optimization suggestions if desired.

The processing time depends, among other things, on the scope of the project, our order situation and our capacities. In most cases, we can process smaller projects promptly.

We require the following data to prepare a quotation:

- 3D cad geometry (step or iges format) or a technical drawing or sketch

- Information on the loads acting on the structure, such as forces, accelerations, pressures, temperatures,

- Information on the materials used

Make a non-binding inquiry and our experts will let you know what additional information we need.

Unfortunately, we cannot give a general estimate of the costs of a flow simulation / CFD calculation, as they depend on various factors. To name just a few examples:

- Geometry: number and complexity of solids

- Material: linear or non-linear

- Connection of the bodies: screw connection, welded connection

- …

Please contact us and we will prepare an individual offer for you.

Do you still have questions about CFD calculation or simulations? Write to us with your request and we will get back to you as soon as possible

Would you like to calculate the flow around systems or vehicles or have temperature calculations carried out? Would you like to evaluate risks in advance using simulation in order to realize shorter development times and thus a faster market entry?

We are your competent engineering office for CFD calculations and work on issues ranging from simple temperature calculations to complex flow simulation models.

KONSCHA Simulation GmbH

Lerchenstr. 28a

22767 Hamburg

Phone: +49 (0)40 / 2285 9289 – 2

E-mail: info@konscha-simulation.de